GCPSG-013 (2024)

Fundamentals of Glazing in Physical Security

On this page

List of figures

Forward

Fundamentals of Glazing in Physical Security is an unclassified publication, issued under the authority of the Royal Canadian Mounted Police Lead Security Agency for Physical Security (RCMP LSA).

This is a Government of Canada publication to serve as a guide for addressing the implications glazing choice has on physical security for departments, agencies and employees of the Government of Canada.

Suggestions for amendments and other information can be sent to the RCMP Lead Security Agency rcmp.lsa-grc.posm@rcmp-grc.gc.ca.

Reproduction

This publication may be reproduced verbatim, in its entirety, without charge, for educational and personal purposes only. Written permission from the RCMP LSA is required for use of the material in edited or excerpted form, or for any commercial purpose.

Effective date

The effective date of GCPSG-013 - Fundamentals of Glazing in Physical Security is 2024-05-01.

Record of amendments

No amendments

Note: Authority for modifications or variances is Royal Canadian Mounted Police Lead Security Agency for Physical Security (RCMP LSA).

1. Introduction

The RCMP, as the Lead Security Agency for Physical Security for the Government of Canada (GC) is responsible for providing advice and guidance on all matters relating to physical security.

1.1. Purpose

The purpose of this document is to provide information on a variety of glazing options available within Canada and their application and efficiency as a safeguard to mitigate risk to staff, information and assets. Note that the information found within this document does not supersede any legislative or legal requirements for the construction of GC facilities (fire codes, building codes).

1.2. Applicability

This guide applies to GC employees involved in the design, construction, retrofit, and/or assessment of GC facilities that will include the use of glazing. The intended audience of this guide includes physical security practitioners, and staff with risk management authority or their delegates.

1.3. Equity, Diversity, and Inclusion in physical security systems

All employees of the Government of Canada (GC) have a responsibility to safeguard persons, information and assets of the GC. It is important that security policies and practices do not serve as barriers to inclusivity, but instead support and respect all GC personnel while ensuring appropriate security measures are maintained for the protection of GC personnel, assets, and information.

Initiatives to promote equality and inclusion among the diverse communities and heritages within the GC, should be respected in the development and maintenance of physical security systems. Departments and agencies should follow all GC legislation, policy and directives on Equity, Diversity, and Inclusion (EDI) in the promotion of a fair and equitable work environment for all persons while ensuring they meet their mandated security responsibilities.

Departments and agencies should conduct a risk management exercise to ensure, that while the dignity of all is respected, the protection of GC information, assets, and personnel is maintained. All questions on EDI policies and directives should first be addressed to your responsible departmental authority.

1.4. Information Technology considerations

With the constantly evolving threat landscape, and the convergence of physical and information technology (IT) security, the requirement to assess the risk of any application and/or software connected to a network to operate and support equipment in GC controlled buildings is critical. Some examples of these control systems could be for items such as, but not limited to, security lighting, perimeter gates, doors, Heating Ventilation and Air Conditioning (HVAC), etc.

Before implementing any applications and/or software that will control and/or automate certain building functions, your departmental security requires the completion of a Security Assessment and Authorization (SA&A). This will ensure that the integrity and availability of the components the applications and/or software controls are maintained and that any risks highlighted will be mitigated. Starting the SA&A process early is highly recommended to ensure project delivery schedules are not affected. For more information on the SA&A process, please consult your departmental Security.

2. Contact information

For more information, please contact:

-

Royal Canadian Mounted Police

Lead Security Agency for Physical Security

73 Leikin Drive, Mailstop #165

Ottawa ON K1A 0R2

3. List of acronyms

3. List of acronyms

- AP

- Armour Piercing (Ammunition)

- COTS

- Commercial-off-the-shelf

- DBT

- Design Based Threat

- DSM

- Directive on Security Management

- FMJ

- Full Metal Jacket (Ammunition)

- JSP

- Jacketed Soft Point (Ammunition)

- LRHV

- Long Rifle High Velocity (Ammunition)

- NIJ

- National Institute of Justice

- PGS

- Policy on Government Security

- SA&A

- Security Assessment and Authorization

- SP

- Soft Point (Ammunition)

- SWC

- Semi-Wadcutter (Ammunition)

- TBS

- Treasury Board Secretariat of Canada

- TRA

- Threat and Risk Assessment

- UL

- Underwriters Laboratory

4. List of definitions

4. List of definitions

- Commercial-off-the-shelf

- Equipment that is not specifically manufactured to user specifications.

- Delay

- The time to defeat a security layer after detection of the attempt.

- Design Based Threat

- A profile of the type, composition, capabilities, methods, projected harm, and/or intensity of a deliberate, accidental, or natural threat upon which the security engineering and operations of a facility is based.

- Glazing

- Transparent material used for windows.

- Mitigate

- Activities taken to reduce risks that may be identified through the TRA process.

- Residual Risk

- The risk that remains after safeguards have been selected and implemented.

- Shrapnel

- Fragments of a bomb, shell, or other object thrown out by an explosion.

- Threat

- Any potential event or act, deliberate or unintentional, or natural hazard that could result in a compromise.

- Threat Risk Assessment (TRA)

- Assessment of a facility to identify risk, threats and vulnerabilities to assets (information, employees, services, etc.).

- Vulnerability

- An inadequacy related to security that could increase susceptibility to compromise or injury.

5. Glazing styles and considerations

Glazing is available both custom made and commercial-off-the-shelf (COTS) and comes in a wide range of configurations with various building materials and manufacturing processes. This section will highlight the security considerations for the most common glazing options to assist in finding the best fit for a project and provide a baseline of the strengths and weaknesses to consider when conducting Threat Risk Assessments (TRA) or other vulnerabilities and risk assessment duties. Consideration should be given to the window frame and how it is anchored to the building structure. Even the strongest glazing solution provides no security value if they can be forcefully removed. A frame must be able to withstand the same level of force as the glaze itself in order to properly mitigate a threat. Most COTS products have framing solutions available and tested to the same level as the glaze, or will have specifications on how to install the product properly to meet the manufacturer's stated ratings and function.

5.1. Annealed glass

Annealed glass, also referred to as sheet, plate, or float glass, is the most commonly found type of glazing. Although inexpensive, annealed glass does not provide realistic protection against forced entry, privacy of speech, nor communications signals. Annealed glass can present additional vulnerabilities as large broken pieces pose a risk to accidental injury or as an opportunistic weapon for a threat actor.

5.2. Tempered glass

Tempered glass has approximately three (3) to five (5) times the strength of annealed glass; providing a greater delay to forced entry. Tempered glass is engineered with tension in the center of the glass while the surface is compressed. When broken, the entire sheet of tempered glass disintegrates into small cube-like pieces, minimizing the damage these can cause a person. Due to this engineered tension, tempered glass has a risk of spontaneous breakage; with any damage from the manufacturing or installation process amplifying this vulnerability. Tempered glass is commonly found as the side windows for vehicles.

5.3. Chemically strengthened glass

Chemically strengthened glass has increased strength as a result of a post-production chemical process. It is typically six (6) to eight (8) times more resistant than annealed glass, and when broken creates similar large shards. Chemically strengthened glass is not commonly used in security or safety applications for this reason.

5.4. Heat strengthened glass

Approximately twice as resistant to breakage as annealed glass, heat strengthened glass is designed to provide increased resistance to high thermal and wind loads. If heat strengthened glass should break, the pieces will be larger and less likely to fall out of a properly installed window frame. This can prove less hazardous to personnel in the event of accidental breakage, but will not provide a meaningful increase to the delay factor of a forced entry attempt.

5.5. Laminated glass

Laminated glass is at least two (2) pieces of various types of glass bonded with plastic. Additional layers of glass can be bonded in the same fashion to increase the strength of the finished product; this can result in the laminated glass passing ballistic and blast resistance tests. Laminating glass does not prevent breakage; however, it adds a resistance by holding the broken layers together within the frame. This allows a barrier to be maintained even after breakage, and greatly increases the forced entry delay factor over non-laminated glass.

5.6. Wired glass

Wired glass is a style that imbeds square or diamond grid wire into the glass as it is being manufactured. This process can be done with annealed, heat strengthened, tempered, or laminated glass. Wired glass is generally required to meet fire and safety codes, as it will hold the broken shards in place if the glass were to shatter limiting the spread of heat and gasses. Recent revisions require wired glass to be impact resistant if installed in an area where people can come in contact with it, such as doors and windows found in walkways. Ensure the use of wired glass is compliant with legislation and local safety codes before considering it for a security application. The wire does not increase the glass's resistance to breakage and will perform similarly to the non-wired variants. The wire is for safety purposes and will not significantly increase the delay factor in a forced entry attempt however, glass held in the frame by the wire would need to be manually removed before a threat actor could gain entry, slightly increasing the delay factor for an unmotivated/unskilled attacker.

5.7. Ceramic glass

Ceramic glass is the least resistant to impact of all glazing options covered in this guide. It performs worse than annealed glass, with similar large pieces produced when broken. Laminating ceramic glass may help keep the broken shards in place and maintain a barrier in the event of breakage, but it will not increase the resistance to impact. The benefit of ceramic is it has the highest resistance to heat of all the glazing options; with many products capable of withstanding sustained temperatures in excess of 500 degrees celsius for a prolonged period of time. This makes ceramic a choice materiel where heat resistance is the primary concern, but is of limited use in a security setting compared to other options.

5.8. Glass blocks

Glass blocks are a highly customizable type of building material and can be manufactured with specific resistances to meet the needs of a project. Due to their thickness, glass blocks are generally resistant to vandalism, forced entry, and may pass ballistic tests. Although the thickness greatly increases the delay factor of a forced entry attempt, a sustained and uninterrupted attacker could chip away at the glass until a large enough breach is created to gain entry or introduce hostile devices into the facility. Glass blocks often distort images beyond recognition allowing for some privacy while still permitting natural light to shine through. Glass blocks perform better than annealed glass for thermal insulation, sound dampening, and fire resistance. Due to the highly varied manufacturing methods used in glass block production, tests should be conducted on the specific product to be used in a facility, including the adhesive structure for bonding the blocks, thus ensuring it meets the identified requirements.

5.9. Plastic

Plastic glazing options are manufactured using either acrylics or polycarbonate. Both materials are approximately half the weight of annealed glass, while performing significantly better against impacts. Acrylic is approximately 17 times more resistant than annealed glass, and polycarbonate is about 300 times more resistant. Polycarbonate is commonly used in riot shields. Both materials have similar disadvantages, both can be scratched without much difficulty, deform when exposed to excessive heat, and are vulnerable to combustion. Fire codes heavily restrict the use of plastic glazing options in facilities; therefore, when considering plastic glazing, ensure it is compliant with all applicable safety and fire codes.

5.10. Glass clad polycarbonate

Glass clad polycarbonate is a polycarbonate sheet laminated with glass. The product is highly customizable with multiple layers of varying thickness being available. This can increase the final product's resistance enough to pass any level of ballistic test, and pass many blast tests. The exterior glass layer protects against marking and provides resistance to fire and heat, both of which are vulnerabilities of unclad polycarbonate sheets. The polycarbonate core provides impact resistance, but will not prevent the glass layer from breaking on impact. This will cause a spiderweb break pattern with the shards remaining bonded to the plastic core, greatly reducing the risk of injury. The material is prone to delaminating, which may affect transparency and reduce visibility though the glazing.

6. Security glazing

Security glazing comes in many different styles designed to mitigate specific threats or vulnerabilities. Many can perform well in categories for which they were not specifically designed and proper analyses of the risks a security glaze is meant to address should be conducted to ensure the best option is utilized. The most common types of glaze used in a physical security setting are laminated glass, plastic, and glass clad polycarbonate. A TRA should be conducted to identify likely threats targeting the facility and any vulnerabilities that require mitigation. Common threats are explored below, however a TRA may identify more sophisticated threats requiring additional considerations.

6.1. Forced entry resistance

The ultimate goal of an adversary attempting to force their way in through glazing is to create a breach large enough for a human to fit through. An attacker can be delayed by utilizing a strong glazing option, such as Glass Clad Polycarbonate, that is highly resistant to breaking when exposed to applications of force. These glazing options may have a higher cost on installation but they can reduce costs in the long run if a high probability of multiple vandalism or forced entry incidents are anticipated. This is due to the likelihood these glazing types will only need to be replaced if the glazing is broken; something an unskilled or unmotivated attacker is unlikely to achieve. Facilities that are less likely to experience an incident may consider using a glazing option with a lesser resistance to force, but can hold broken shards in the frame after an incident. The glaze will need to be replaced after the incident however, security films or laminated glazes will hold the shattered pieces in place. This will delay an attacker as they are forced to manually remove the shards to create a breach large enough to fit through. The risk of injury can provide a psychological deterrent as well for unmotivated threat actors, as glass shards remaining in the frame pose a serious risk to injury even after a breach is created.

6.2. Bullet resistant glazing

While there is no material that is completely “bulletproof” a great deal of research and development have been devoted to bringing materials as close to this as possible and glazing is no exception. Glazing can achieve a level of ballistic protection to safeguard against most conventionally available handgun and rifle calibers. There are standardized ballistic rating to determine what each glazing solution can safeguard against. The most commonly used systems are UL 752 Bullet Resisting Equipment and the National Institute of Justice (NIJ) Standard 0108.01.

The UL 752 Bullet Resisting Equipment is generally preferred by engineers as it is more technically specific however, the broader NIJ Standard is sufficient if the identified threat is addressed by the standard. As bullet resistant glazing is extremely heavy, it must be housed in a frame capable of holding its weight in addition to the force generated by a ballistic threat. It should be noted that the walls around bullet resistant glazing should be capable of withstanding equal or greater ballistic profiles than the glaze. Bullet resistant glaze is of limited use if rounds can penetrate the wall surrounding it.

| UL Rating Level | Ammunition | Bullet Mass | Velocity m/s | Number of Shots |

|---|---|---|---|---|

| Level 1 | 9mm FMJ Lead Core | 8g | 358 | 3 |

| Level 2 | .357 Magnum JSP | 10.2g | 381 | 3 |

| Level 3 | .44 Magnum Lead SWC Gas Checked | 15.6g | 411 | 3 |

| Level 4 | .30 Cal Lead Core SP | 11.7g | 774 | 1 |

| Level 5 | 7.62mm FMJ Lead Core | 9.7g | 838 | 1 |

| Level 6 | 9mm FMJ Lead Core | 8g | 427 | 5 |

| Level 7 | 5.56mm FMJ Lead Core | 3.56g | 939 | 5 |

| Level 8 | 7.62mm FMJ Lead Core | 9.7g | 838 | 5 |

| Level 9 | AP .30 Cal FMJ Steel Core | 10.8g | 828 | 1 |

| Level 10 | .50 Cal FMJ Lead Core | 45.9g | 856 | 1 |

| Supplementary Shotgun | 12-Gauge Rifled Slug | 28.3g | 483 | 3 |

| 12-Gauge 00 Buckshot | 42g | 366 |

| Armour Type | Test Ammunition | Nominal Bullet Mass | Required Bullet Velocity | Required Hits Per Armour Specimen |

|---|---|---|---|---|

| Level 1 | .22 LRHV Lead | 2.6g | 320 ± 12m/s | 5 |

| .38 Special RN Lead | 10.2g | 259 ± 15m/s | 5 | |

| Level 2-A | .357 Magnum JSP | 10.2g | 381 ± 15m/s | 5 |

| 9 mm FMJ | 8.0g | 332 ± 12m/s | 5 | |

| Level 2 | .357 Magnum JSP | 10.2g | 425 ± 15m/s | 5 |

| 9 mm FMJ | 8.0g | 358 ± 12m/s | 5 | |

| Level 3-A | .44 Magnum Lead SWC Gas Checked | 15.55g | 426 ± 15m/s | 5 |

| 9 mm FMJ | 8.0g | 426 ± 15m/s | 5 | |

| Level 3 | 7.62mm | 9.7g | 838 ± 15m/s | 5 |

| .308 Winchester FMJ | 9.7g | 838 ± 15m/s | 5 | |

| Level 4 | 30-06 AP | 10.8g | 868 ± 15m/s | 5 |

6.3. Bomb blast resistance

It is not effective or practical to attempt to completely mitigate the risk to life in a blast event using only glazing and regardless of safeguards implemented, there will likely be considerable damage to the infrastructure. When a blast threat requires mitigation, glazing solutions should be designed to minimize shrapnel created and disperse the energy from the shockwave. This can be done by ensuring the glaze is securely anchored to a frame rated to withstand an equal or greater force to the glaze. If the frame is weaker than the glaze, the glaze may separate in a blast event and become a lethal piece of shrapnel. Shrapnel can be decreased by adding laminated layers of glass, or polycarbonate, to hold as much of the damaged glaze in the frame as possible. Tempered glass also produces smaller shrapnel, but can still cause serious injury. When considering blast resistance, consider other factors such as standoff distance or the deployment of blast curtains or other armouring in addition to the glazing. Refer to RCMP guide GCPSG-002 Blast Considerations Guide.

6.4. Glazing to deter electronic eavesdropping

There are purpose-made products that can be installed or implemented in a retrofit that can provide reasonable bolstering on emissions security in a facility, which can bring glazing choices into compliance with secure digital communication levels. Contact Communications Security Establishment for more information and guidance on emissions security and safeguarding against electronic threats.

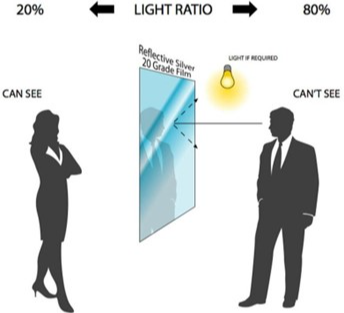

6.5. One-Way/Mirrored Glaze

Glazing can be modified so that it only allows viewing in one direction, commonly referred to as mirrored glass or one-way glass. This is achieved by “half silvering”, which is applying a silver film on the side being observed that only allows half of the light to pass through, reflecting the rest to give an appearance similar to a mirror from the side being observed. For this effect to function, the side being observed must be brightly lit, with the observing side being a room with a very low lighting. If the observing side has too much light then a subject on the observed side will be able to see through the half silver, rendering the one- way film ineffective. One-way glass has limited uses in security beyond covert observation, and even this is better achieved with the use of electronic surveillance. The one advantage of one-way glass is it can continue to function in the event of power failure, should the appropriate lighting be maintained through non-electronic means (for example, natural light on the side being observed).

Figure 1 - One-way mirror

7. Complementary safeguards

There are multiple additional safeguards that may complement a glazing system without being directly applied to the glaze. These complementary systems may help bridge the gap between shortcomings in a glazing system's security profile, and may bring the residual risk within acceptable levels when measured together.

7.1. Film

Security film is a popular option for target hardening an existing facility, especially where operational or budgetary requirements prevent replacing the existing glazing. Security film is applied directly to an existing glaze and may improve the effectiveness over the safeguard's baseline purpose. When applied, security film will increase the performance of existing glaze by holding broken pieces together in the event of a break, similar to laminated glass options. There are also specialized styles of film that can shield from electronic emissions, improving the emission security of the glazing to which it is applied. Tinted options exist for glazing film that can increase privacy and effect thermal insulation. These benefits may include:

- Increased delay factor on forced entry attempts;

- Reduced risk of glass shrapnel;

- Improved emission security shielding;

- Increased visual privacy;

- Low cost; and

- Rapid installation.

Security films can be fitted to most sized windows and can be installed on the interior, exterior, and with multiple layers. In the case of large glazes, multiple film sheets may be needed to treat the entire surface. If multiple sheets are needed, there will be seams which will negatively impact their efficiency. Film sheets should be installed in accordance with the manufacturer's instructions to achieve the desired level of protection.

7.2. Bars and Screens

Bars or screens made from metal can be installed to the frame of a glazing system in order to greatly increase the delay factor of forced entry. This can be cheaper to install or retrofit than forced entry resistant glaze options. Bars and screens are incredibly difficult to damage which can save on repairs as many glazes require replacement even when they successfully stop an attack. Bars and screens are also highly visible and can provide a psychological barrier to low skill or low motivation attacker who may search for an easier target rather than attempt to defeat these safeguards. Bars and screens do not have a notable effect on ballistic or blast performance. In a blast event, the bars and screens may become shrapnel, increasing the lethality of an explosion. As noted in 5.6 Wired glass, building and fire safety codes may prohibit the use of bars and screens as a complementary safeguard. Consult local authorities during the planning phase of any project to install these features.

7.3. Alarms

Alarms should always be considered when applying and measuring safeguards for a facility, even the most robust prevention measures can be overcome if a threat actor is given unlimited time. Alarms can provide a localized response, such as a loud audible cue or strobe light to frighten away a low skill or unmotivated threat actor. Alarms can also trigger a physical response, either from a police service of jurisdiction or private security company, to the incident location. Refer to RCMP guide (GCPSG-019 Protection, Detection, Response, and Recovery) for more information on detection of and response to a security incident.

7.4. Blast Curtains

Blast curtains are added barriers, made from blast or ballistic rated materials such as Kevlar and designed to act as a catchment system for shrapnel or as a buffer or shock absorber for the pressure wave caused by an explosion. Depending on their manufacturing method, blast curtains can withstand a wide range of incident intensities. Blast curtains are not required to be installed permanently, and may be an alternative for facilities that have varying threat landscapes, such as multi-tenant office towers. Blast curtains can be stored on site and be applied to increase the security posture rapidly to respond to threats not faced in general, day-to-day activities. A baseline Design Based Threat (DBT) should be identified before engaging a supplier, who could then assist in the selection of or custom designing of, a blast curtain and supporting anchorage to meet the needs of the project.

8. Conclusion

Glazing products are highly modular and customizable, with solutions that can be implemented at various stages of any project. An understanding of the threat environment is as important as understanding of the available glazing solutions. Once a threat has been identified, an appropriate glazing option may be selected and implemented. Manufacturers of security glazes can work with a department or agency's physical security team to identify a COTS or custom product to efficiently mitigate a range of risks faced by a facility. Glazing is an important consideration for the physical security and defence-in-depth of nearly every facility.

9. Reference and related documents

- Policy on Government Security

- Directive on Security Management

- UL 752 Bullet Resisting Equipment- 11th Edition

- NIJ Standard 0108.01 Ballistic Resistant Protective Materials

- GCPSG-019 (2023) Protection, Detection, Response, and Recovery Guide

- GCPSG-002 Blast Considerations Guide

- G1-003 Glazing (04/2000) (Archived)

- Migo Glass: How one-way mirrors work

- Call to Action on Anti-Racism, Equity, and Inclusion in the Federal Public Service

- Directive on the Duty to Accommodate

- Guide for Two-Spirit, Transgender, Non-Binary, and Gender-Diverse Employees in the Federal Public Service

10. Promulgation

Reviewed and recommended for approval.

I have reviewed and hereby recommend, GCPSG-013 (2024) - Fundamentals of Glazing in Physical Security, for approval.

Shawn Nattress

Manager, RCMP Lead Security Agency

Date: 2024-04-30

Approved

I hereby approve GCPSG-013 (2024) - Fundamentals of Glazing in Physical Security.

Andre St-Pierre

Director, RCMP Physical Security

Date: 2024-05-08

- Date modified: